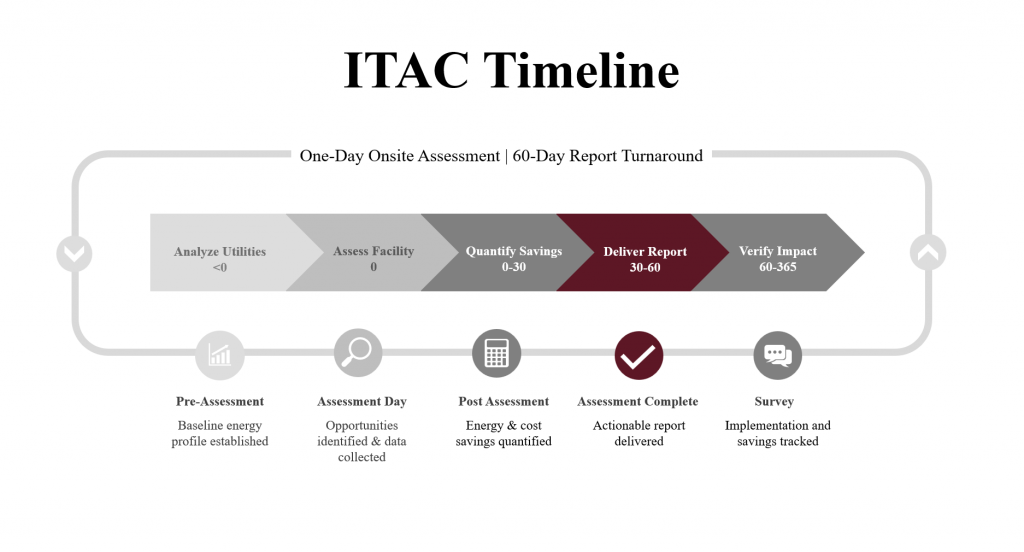

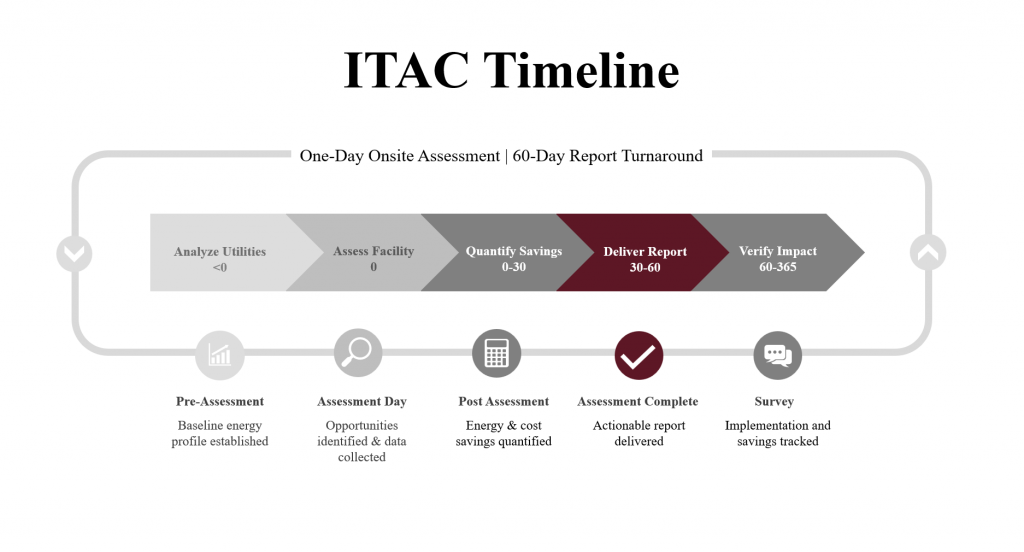

Protocol

STEP 1: Pre-Assessment Information Gathering

Client is sent a Pre-Assessment Form. This form includes:

- Size of plant and plant layout

- Industry type (SIC/ NAICS code)

- Production levels, units and dollars, operating hours

- A one year history of utility bills

STEP 2: Ensure that key plant personnel are involved

- Plant manger

- Energy manager

- Environmental personnel

- Maintenance personnel

STEP 3: Pre-Assessment Analysis

- Analyze the manufacturing process

- Chart and graph utility bills

- Analyze utility bills for trends and errors; establish unit cost of energy

- Review design and other technical documentations

- Develop Assessment Day Strategy

STEP 4: Day of the Assessment

- Introduction

- Description of manufacturing process and operations

- Plant Tour

- Meeting room debriefing

- Review notes and brainstorm (Lunch)

- Refine list of opportunities to be investigated

- Data Gathering

- Exit Interview

STEP 5: Post Assessment Activities

- Conduct engineering and financial analysis

- Contents of an ITAC Report

- Executive Summary (including summary of recommendations)

- Plant Description

- Process Description

- Resource Charts and Tables

- Major Energy Consuming Equipment

- Best Practices

- Description of Individual Energy Saving Recommendations

- Follow-up to Report

- Call client in two weeks to ensure delivery and answer questions

- Call client in 6-9 months for implementation data

- Inquire about potential for Case Study of project(s)